In 1912, Kuzuri Keori Kogyo Co., Ltd. was founded in Kisogawa-cho, Ichinomiya, along the banks of the Kisogawa River. Kuzuri Keori Kogyo is a longstanding wool textiles manufacturer that uses exclusively Schönherr equipment; a type of low-velocity Japanese loom that became widespread in the country around the 1950s.

As a result, Kuzuri Keori produces a range of unique, value-added textiles unavailable anywhere else in the world. The Kuzuri Keori Kogyo plant is a nostalgic wooden building with a sawtooth roof, allowing for natural light to slide in and dapple the vintage machinery, whilst the slow-moving Schönherr looms beat to their own rhythm.

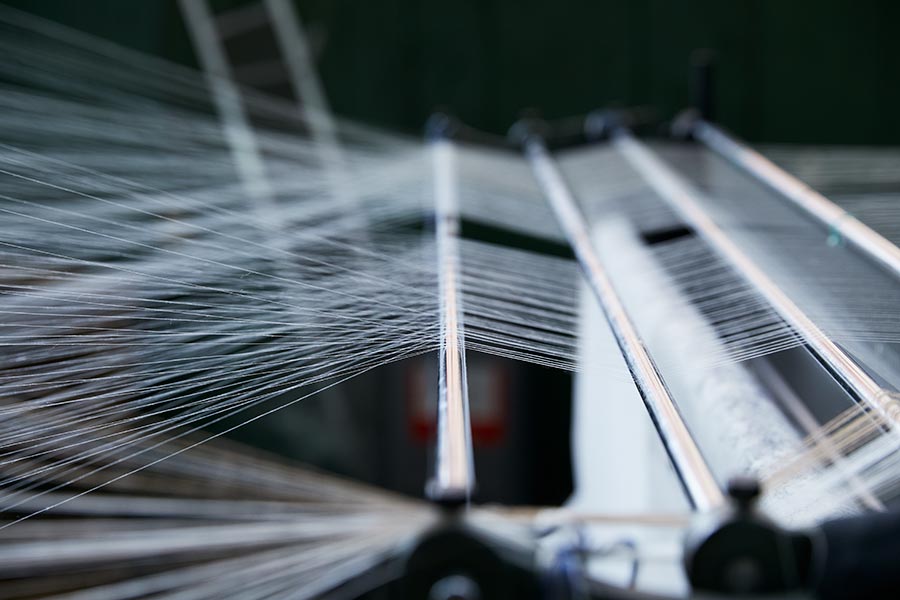

When weaving, Schönherr looms employ traditional shuttles to move the warp thread left to right. Most weavers long ago discarded shuttle looms for their low productivity and opted instead for air jet and other high-speed, cutting-edge technology. It is quite natural that weaving, which began by hand, would be outfitted with machine power over time and become unmanned in the pursuit for speed and efficient production, with machines being updated to the latest style. However, Kuzuri Keori Kogyo has found a way to tap into new possibilities using these Schönherr looms, which are closer to hand-weaving than current machinery, thereby developing a product that mass production workflows cannot.

Yukio Kuzutani, the third-generation owner of the business, looks back on the deciding factors behind the company’s trajectory, “As more and more weavers sought high speed and productivity, we felt their product was becoming uniform. We did not like where that was going, as it implied a loss of creativity. We decided to opt for craftsmanship to bring out the feel and texture of the wool.” Kuzuri Keori Kogyo takes on even the most challenging of orders and delivers results, leading the company to be a preferred manufacturer amongst Japanese designers and tailors, and even buyers from some of Europe’s top haute couture houses.

Gallery

Operating ten Schönherr looms, Kuzuri Keori Kogyo’s factories use a process in which the warp thread is prepared and yarns of exact lengths are drawn, a heddle is used to move the warp thread up and down, a device then adjusts the width of the fabric and passes the weft thread through the warp, the weft is prepared, and finally, handweaving and inspections finish the process. This complex work takes up to ten days before the actual weaving by loom can begin, and is entirely done by hand. While the latest high-speed loom can produce several hundred meters of cloth in a day, Schönherr looms can only weave fifty meters, taking three or four days.

Kuzuri Keori Kogyo has been in managing director Akira Kuzutani’s family for four generations, who said, “Wool is like a living creature.” Slow weaving without applying too much tension to the warp or weft is essential to maintaining the unique feel of the wool fabric; which is why Schönherr looms are an excellent fit for this material. Taking time to prepare wool – a material that breathes – in this way allows the wool to stay in a relaxed state.

The more heddles used in the loom, the more complex the textile that can be made. While ordinarily eight heddles are used, Kuzuri Keori Kogyo has Schönherr looms that use sixteen, twenty, twenty-two, or even as many as twenty-four heddles. These produce the complex and rich textiles that the company is known for.

The Kuzuri Keori Kogyo plant even has Schönherr looms that have been in operation since 1932, when the machines first entered the market. These machines are closely maintained and are still weaving to this day. When parts break, they are repaired by local blacksmiths, adding to the unique particularities of each loom; some have a smooth surface where the yarn makes contact, and others are equipped to handle different materials or yarn counts.

Each year, more and more young people are seeking work at Kuzuri Keori Kogyo, due to its reputation for having a hospitable and passionate culture. Managing director Akira Kuzutani says, “We had our 100th anniversary in 2012. We certainly want to keep going another one hundred years.” Known for impressing textile aficionados the world over, it’s worth watching with interest the wool textiles that come out of this company.