COLOURizd™ QuantumCOLOUR™ is a revolutionary wool yarn colouring process that can significantly reduce resource consumption.

COLOURizd™ QuantumCOLOUR™ TECHNOLOGY

COLOURizd™ QuantumCOLOUR™ for wool yarn is a water-saving, lower-impact colouring technology, with greige yarn passed through a continuous process without the use of water. Developed by injecting pigment and a binder into a yarn fibre bundle, this process passes wool yarns through a drying and curing unit at a pre-selected temperature and allows for a range of colours and textures. The Quantum COLOUR™ process provides durable solutions, creating faded to saturated tonal depths of colour for wool and wool blends. And since it uses very little water, suppliers can choose to colour wool and wool blend yarns without the need for wastewater processing infrastructure.

Using just 0.5L of water per kilogram of yarn, this technology eliminates the need for bleaching, pre-treatment and wastewater discharge. This makes COLOURizd™ QuantumCOLOUR™ a reduced resource-intense colouration process, where only the wetting agent and pigment binder system are required.

Creating a full spectrum of colours including brights, lights and darks, the COLOURizd™ QuantumCOLOUR™ method eliminates the variability commonly associated with conventional dyeing techniques, such as shade bands, to support repeatable, controlled application of colour. The result is a wool yarn with the capacity to deliver diverse shades of colour for both knitted and woven textiles across apparel and homeware.

Tested against Woolmark quality control test methods, the COLOURizd™ pigment process for wool meets all standards for colourfastness and durability. Assessed through our authorised laboratory partners, Woolmark testing was carried out on yarns, fabrics and garments, showing that the technology delivers consistent colour performance and long-lasting wear.

With guidance from our technical team, the technology was successfully validated on 100% Merino wool, as well as blends with cotton, TENCEL™ and nylon, on a range of yarn counts from 30/2NM to 80/1NM. This broad trial on wool yarn types showcases the improvement of pigment colour performance by way of COLOURizd™ QuantumCOLOUR™ while maintaining excellent yarn quality.

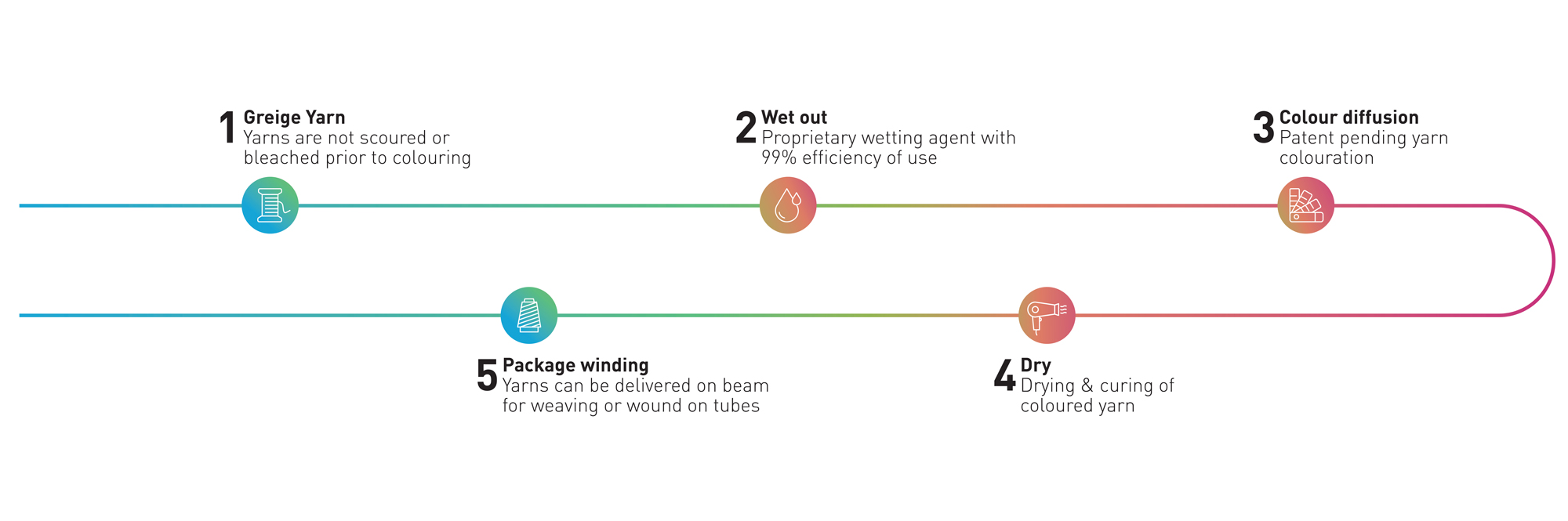

COLOURizd™ QuantumCOLOUR™ Process

COLOURizd™ QuantumCOLOUR™ Benefits

COLOURizd™ QuantumCOLOUR™ technology presents a variety of benefits including reduced water consumption through the colouring process, lower energy use as dyeing occurs at room temperature, decreased chemical waste where less dyes and finishing agents are required and elimination of pre-treatment steps and minimised wastewater.

Unlike traditional dyeing methods, which rely on large amounts of water and multiple chemical treatments, the COLOURizd™ QuantumCOLOUR™ dyeing process uses minimal water. While not entirely waterless, COLOURizd™ QuantumCOLOUR™ consumes only 0.5L of water per kilogram of yarn, which provides a significant reduction when compared to fibre reactive dye.

One of COLOURizd’s key advantages for the wool industry is its ability to colour multiple fibre types - such as wool, cotton, and synthetics - in a single pass using one chemistry. This eliminates the complexity and cost typically associated with cross dyeing, a process that often leads to inconsistency and high resource consumption. By removing this barrier, COLOURizd™ enables mills and manufacturers to work with wool blends more efficiently, while achieving consistent colour, reduced waste, and streamlined production.

The precision of this technology ensures the optimum dosing of wetting agents, pigments and binders are used, minimising chemical wastage, as well as the elimination of pre-treatment steps. COLOURizd™ QuantumCOLOUR™ technology does not require bleaching or other pre-treatments prior to dyeing, with no wastewater discharge from its process, making it a solution to reduce environmental impact while preserving consistent colour for innovative designs.

Contact the Woolmark Technical Team for more information.