Revolutionise your knitwear creativity with whole garment knitting technology to maximise comfort, minimise waste and explore sophisticated knitting machine options for unique apparel and footwear.

Whole Garment Knitting Technology

La laine la plus agréable au monde

Plus fine qu’un cheveu humain, la laine Mérinos n’a rien à envier au cachemire et sa douceur est appréciée par les peaux les plus délicates.

Moins d’énergie. Moins d’eau

La production de 100 pulls en laine nécessite 18 % d’énergie en moins que le polyester et 70 % d’eau en moins que le coton.

Pas de microplastiques, moins d’enfouissement

Contrairement aux tissus synthétiques, la laine n’est pas constituée de pétrole, mais de kératine. Elle est entièrement biodégradable et ne contribue pas à la pollution par les microplastiques de nos océans et de nos terres.

How it works

Originally developed from V-bed machines, modern whole garment machines have multiple needle beds, arranged in a V formation. The knitting action occurs by a single yarn completing a horizontal traverse of the machine bed.

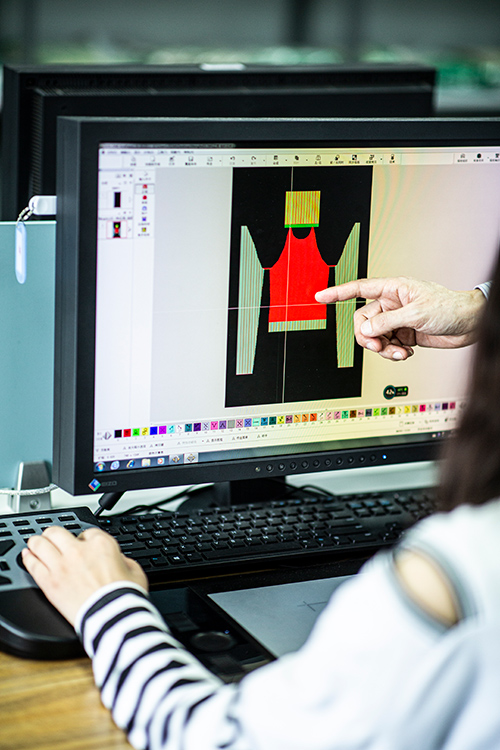

Harnessing computer-aided design (CAD) tools for both design and production, whole garment knitting requires next-to-no finishing and extends the options for Merino wool, from structured casual wear through to unstructured sportswear. Whole garment technology can also create a garment with no seams for superior appearance and next-to-skin comfort.

Partners Using Whole Garment Knitting Technology

Our key partners for whole garment technology include SHIMA SEIKI, Karl Meyer and STOLL, creating seamless garments that wrap the body for an ideal fit, minimising textile waste, maximising comfort and offering a relaxed garment appearance.

Contact us to learn more.

Advanced Knitting Technologies

Develop your knitwear process and boost creativity with the latest advanced technologies to enter the market. With innovative knitwear machinery and emerging spinning processes and yarns, the latest advanced knitting technologies present new potential for knitted wool garments.

Explore the journey of knitted garments through the evolution and use of knitting machinery. With knitwear design ever evolving alongside advances in knitwear technology, harness the dynamic opportunities for wool apparel and accessories innovation. From circular knitting to warp knitting and flat bed knitting to complete garment creation, discover the unlimited creative possibilities of advanced knitting technologies.

Enter the world of advanced knitting technologies and contact our technical team for more information.