Inspired by circular economics and a desire to do good about the world, the Seljak sisters are turning the wool industry’s scraps into objects of use and beauty.

Picking up waste from the ground isn’t exactly the obvious starting point from which to build a successful business, yet Samantha and Karina Seljak have managed to do just that. With one idea – a wool blanket made by recycling the factory floor offcuts at Australia’s oldest running wool mill – the Seljak brand was born in November, 2015; the outcome of months of research, an inherent passion the Seljak sisters have always had for well-made things, and their sense of responsibility to do something with purpose.

“Sam and I have got this similar value set but we have different ways of doing things that kind of fit nicely together,” reflects Karina. Indeed, it was not long after their first product launch that Samantha moved to Copenhagen to study a master’s degree in Sustainability Leadership, though remains as involved in the company as her sister.

Karina’s experience in the prolific craft food industry in New York City that works on trading and sharing local resources, ingredients, and ideas, proved to be hugely beneficial in building the Seljak business from the ground up. “We wanted to find an Australian resource that we could celebrate,” she explains, “and our research was looking at design concepts like biomimicry and as well as permacultural practices and circular economy methodologies. We looked into the wool industry in Australia and came across the mill that we work with now.”

By identifying Australian wool as a unique resource in the country, Samantha and Karina embarked on building a brand and a product around the fibre. And whilst Karina’s degree in fashion design proved useful in the product development stages, the sisters deliberately eschewed any seasonal approach that a traditional fashion or homewares item would require, or indeed anything that would render their product transient and therefore unsustainable. Instead, focusing on utility, the blanket emerged as a logical outcome; an item that’s simple, forever useful and able to harness the longevity of wool’s fibres. A beautiful blanket, after all, also reduces the need for indoor heating.

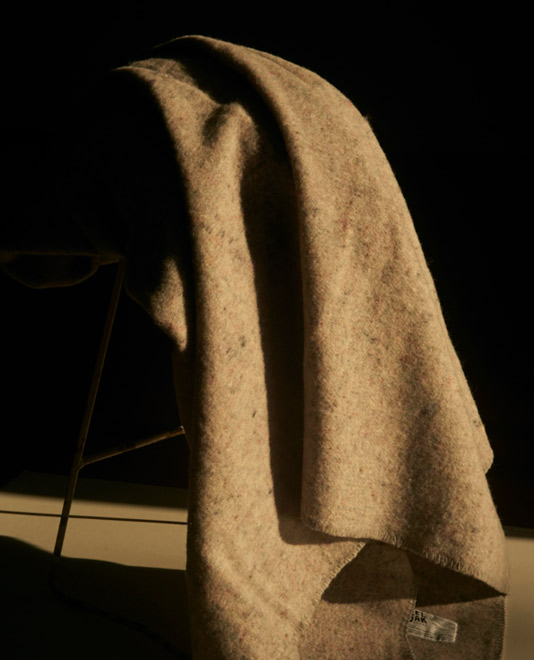

Seljak original blanket with whipstitch

This materials-led approach to sustainable design emerged from early learnings in the sisters’ lives. Karina’s and Sam’s mother instilled a respect for good quality products and materials from very early on, their grandparents on their father’s side were refugees from Slovenia. From this, Karina sees that “We have an inherent resourcefulness,” underlying the core value of their brand today, which in retrospect, was inevitable.

The mill of choice wasn’t, however, immediately convinced by what the Seljak sisters had envisioned for their recycled wool blankets. Despite it being an age-old practice to reuse offcuts from multiple stages of manufacturing in mills, Karina admits, “We were small and were asking them to do something that they didn’t see a lot of value in, but they did work with us willingly every step of the way and now they even internally call the offcuts reclaimed rather than waste.”

With the blankets on the market for around two years now, Karina and Samantha, together with this Tasmanian mill, have refined the customised manufacturing process. Firstly, reclaimed wool is gathered from various stages of the supply chain process – from raw wool to top and yarn, and even partial garments – and is put through an industrial ragging machine, which chops up the pieces into consistent fibre lengths. These pieces are then put through the carding machine, and a bit of polyester (around 30%) is added at the spinning process to bind the fibres. Then the yarn is woven, milled, dried, dyed, raised and finished.

This entire process ensures that these blankets are made to last a lifetime, though Karina and Samantha are working to further improve the environmental footprint of their blankets. The polyester component will soon be replaced by recycled polyester, whilst more time is spent researching and testing how to use new wool as the binding agent with ambitions to create 100% wool blankets.

Seljak original blanket with whipstitch

As integral to the business as the wool fibres themselves is the service Seljak has created whereby customers who no longer want their blankets can send them back to the company, free of charge, to be reintroduced into the supply chain and once again remade into another beautiful new blanket. “I think it is an exciting proposition for people to hear that maybe there are different ways of making things and using them, and disposing of them at the other end of their useful life.”

This closed-loop system that eliminates any contribution to landfill is not the only way the brand looks to rethink established ways of operating a business. For every ten blankets sold, Seljak donates one to The Asylum Seeker Resource Centre in Melbourne; a facility that provides food, job training and basic legal services for those who need it most. “By making such a basic symbol for warmth and comfort, we almost felt it was an obligation,” says Karina. “The migration crisis really peaked as we were developing our business model and product. The plight of refugees has a place in our family history, and we also just understand that having a safe place to be is a basic human right and something that Australia is built on.”

It’s with this approach that produces no waste, gives back to the community, and even uses carbon neutral delivery services, that Seljak has steadily built a following - and demand - for its blankets. “The whole approach of purpose driven business is definitely something people are really engaging with right now,” explains Karina. And while the blankets are not the cheapest on the market, Seljak’s growing customer base connects with the integrity of the brand and understands the value of a beautiful, well-made product that’s completely manufactured in Australia.

Returning to Australia at the end of this year, Samantha will be able to implement the invaluable knowledge and experience she will have gained from what’s considered fashion’s sustainability capital of the world. And whilst Karina refrains from revealing exactly what the future holds for Seljak, her confidence is encouraging. “We're fairly early on in our journey and we've proved that waste-to-resource products are marketable, so now we can embark on an innovation mission to further that.”